益生菌(probiotics),作为改善寄主肠道微生态作用的活性微生物[1],具有增强免疫力[2]、降低胆固醇和延缓衰老[3]等作用。酸奶具有良好的生理功能和丰富的营养物质,是开发功能性食品的理想选择[4]。含有益生菌的酸奶有改善胃肠道[5]和降血脂[6]功效。益生菌产品以乳制品为主,益生菌发酵的酸奶将益生菌本身的发酵性能与酸奶的保健功效结合达到协同作用[7]。益生菌乳制品主要有发酵乳、乳酸菌饮料、干酪、酸奶、乳饮料、奶粉和冰淇淋等等[8],酸奶产品中益生菌的添加为消费者提供了有益的功能[9]。

薏苡(Coixlacryma-jobi L.)为禾本科玉蜀黍族薏苡属,被誉为“世界禾本科植物之王”,其成熟种仁称为“薏米”[10]。薏米富含蛋白质、脂肪、淀粉、矿物质、维生素等营养成分,以及薏仁酯、薏仁油、三萜、谷甾醇、生物碱等活性成分,薏米有降压、降糖、消炎、抑制癌细胞增殖等生理功能[11]。薏米被应用于各种功能保健食品,研究发现,薏米浆与鲜奶发酵后,营养成分更丰富,口味更好[12]。

目前,市售的酸奶大多采用 Lactobacillus bulgaricus 和Streptococcus thermophilu 发酵,但它们耐酸耐胆盐及粘附定殖效果较差,有益作用受到限制[13]。Lactobacillus reuteri 作为益生菌已经被我国批准可用于乳制品、保健食品[5],它有止泻[14]、增强机体免疫[15]、拮抗病原微生物[16]和调节肠道菌群[17]等功能。同时,Lactobacillus reuteri 耐酸耐碱能力较强,为其在肠道内定殖并发挥益生功能创造必要条件[13]。从前期实验对适合罗伊氏乳杆菌生长的功能谷物的筛选得出,薏米能显著促进Lactobacillus reuteri 的生长,活菌数量级高达1013 cfu/mL,罗伊氏乳杆菌单菌株发酵存在凝乳效果差的缺点。因此,本文采用Lactobacillus reuteri 分别与Streptococcus thermophilus和Lactobacillus bulgaricus 协同发酵制备薏米酸奶,剖析其理化指标、质构特性、滋味及挥发性风味物质,以期为Lactobacillus reuteri 的应用及薏米产品的深入研发提供理论依据。

1 材料与方法

1.1 材料与试剂

Lactobacillus reuteri(保藏号BNCC No:186563)购于北京北纳创联生物技术研究院;Streptococcus thermophilus(保藏号CICC No:6247)购于中国工业微生物菌种保藏管理中心;Lactobacillus bulgaricus(保藏号GDMCCNo:1.155)购于广东省微生物保藏中心;薏米、鲜牛奶、白砂糖均市售,MS 培养基、MS 肉汤培养基、酚酞、氢氧化钠、酒石酸、苹果酸、乳酸、柠檬酸、乙酸、草酸、磷酸、磷酸二氢钾等均为分析纯。

1.2 仪器与设备

Pegasus HRT 4D Plus(LECO,USA)全二维气相-高通量高分辨质谱联用仪;1260 高效液相色谱仪,美国安捷伦公司;TS-500Z 电子舌味觉分析系统,日本Insent 公司;TMS-Pro 质构分析仪,美国Food Technology Corporation 公司;JK9870 全自动凯氏定氮仪;pH-25 型pH 计,上海今迈仪器仪表有限公司。

1.3 方法

1.3.1 薏米酸奶的制备

以1:5 的料液比加入纯净水浸泡薏米24 h,煮1.5 h,打浆,加0.3%(中温)α-淀粉酶,55 ℃糊化1 h,加入0.5%糖化酶58 ℃糖化50 min,120 目尼龙布过滤。6%白砂糖、薏米浆30%、鲜牛奶混合均质。95 ℃下灭菌5 min,冷却,接入5% 1:1:1 的菌种,41 ℃发酵6 h,酸奶于4 ℃冷藏24 h,得到薏米酸奶成品。

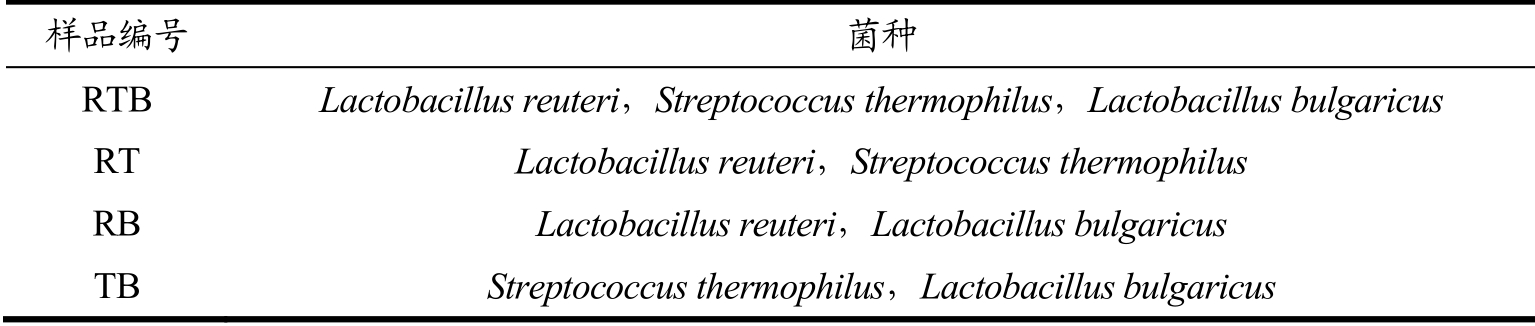

表1 样品详细信息

Table 1 Sampledetails

样品编号 菌种RTB Lactobacillus reuteri,Streptococcus thermophilus,Lactobacillus bulgaricus RT Lactobacillus reuteri,Streptococcus thermophilus RB Lactobacillus reuteri,Lactobacillus bulgaricus TB Streptococcus thermophilus,Lactobacillus bulgaricus

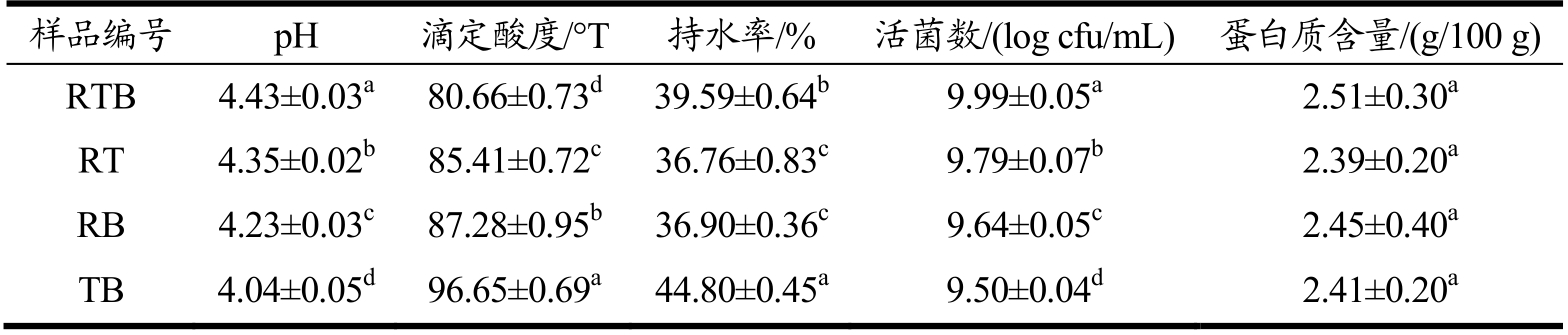

表2 薏米酸奶理化指标

Table 2 Physical and chemical indexes of semen coicis yogurt

注:同列不同小写字母表示样品之间差异显著(p<0.05),下同。

样品编号 pH 滴定酸度/°T 持水率/% 活菌数/(log cfu/mL) 蛋白质含量/(g/100 g)RTB 4.43±0.03a 80.66±0.73d 39.59±0.64b 9.99±0.05a 2.51±0.30a RT 4.35±0.02b 85.41±0.72c 36.76±0.83c 9.79±0.07b 2.39±0.20a RB 4.23±0.03c 87.28±0.95b 36.90±0.36c 9.64±0.05c 2.45±0.40a TB 4.04±0.05d 96.65±0.69a 44.80±0.45a 9.50±0.04d 2.41±0.20a

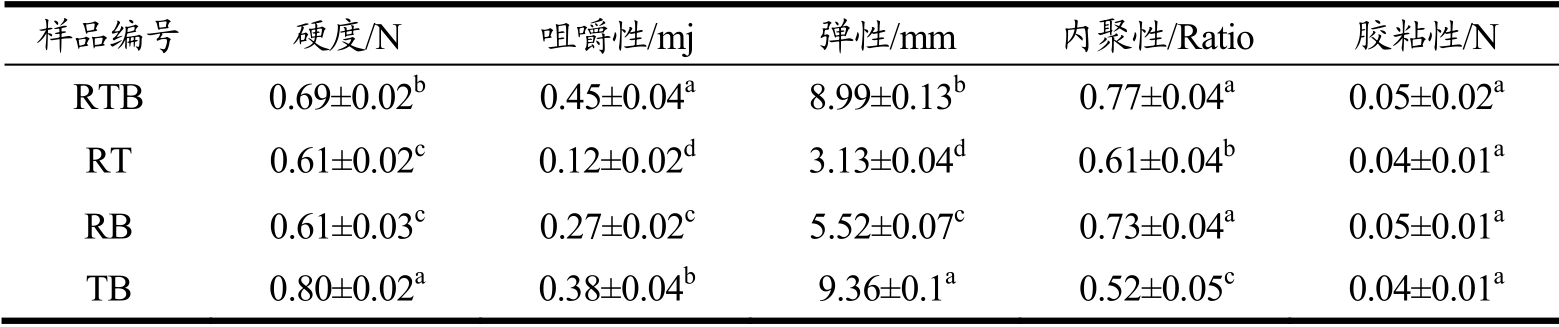

表3 薏米酸奶质构分析

Table 3 Texture analysis of semen coicis yogurt

样品编号 硬度/N 咀嚼性/mj 弹性/mm 内聚性/Ratio 胶粘性/N RTB 0.69±0.02b 0.45±0.04a 8.99±0.13b 0.77±0.04a 0.05±0.02a RT 0.61±0.02c 0.12±0.02d 3.13±0.04d 0.61±0.04b 0.04±0.01a RB 0.61±0.03c 0.27±0.02c 5.52±0.07c 0.73±0.04a 0.05±0.01a TB 0.80±0.02a 0.38±0.04b 9.36±0.1a 0.52±0.05c 0.04±0.01a

1.3.2 常规理化指标测定

滴定酸度参照LIM[18]方法;持水率参考FENGC[19]方法;手持pH 计测定pH 值;活菌数的测定采用平板计数法;蛋白质含量的测定参照GB 5009.5-2016《食品中蛋白质的测定》。

1.3.3 TPA 测试

酸奶的质构测定参考FANG T[20]等的方法略作修改,测试采用连接25N 感应元的质构仪,使用直径为50 mm 探头,测试速率60 mm/min、形变量30%。

1.3.4 有机酸测定

有机酸的测定参照王雪艳[21]等的方法略作修改。色谱条件:磷酸二氢钾溶液(0.02 mol/L);柱温:35 ℃;检测波长:210 nm;进样量:10 μL;流速:1 mL/min。

1.3.5 电子舌的测定分析

电子舌的测定分析参考王一然[22]的方法略作修改,取适量体积的酸奶5000 r/min 离心10 min,加2倍体积的超纯水稀释,取25 mL于电子舌专用杯测定。

1.3.6 挥发性风味物质的测定

挥发性风味物质的测定参MOINEAU-JEAN A[23]的方法略作修改,采用SPME-GC-MS 技术对酸奶进行定性及定量分析。

1.3.7 数据处理

采用SPSS 22.0和Excel处理软件对数据进行统计分析,实验重复三次,Duncan 检验法进行差异显著性分析,p<0.05 表示差异显著。

2 结果与分析

2.1 理化指标

酸奶的pH 和滴定酸度取决于菌种种类、接菌比例和菌种产酸能力,酸度是衡量酸奶品质的重要指标[24]。由表2 可以看出,薏米酸奶pH 在4.04~4.43,滴定酸度在80.66~96.65 °T,而RTB 滴定酸度是80.66 °T,显著低于其他两菌发酵的酸奶(p<0.05),这与温夏萍[25]研究结论一致,Lactobacillusreuteri 发酵乳糖主要产生乳酸、碳酸和乙酸,碳酸不稳定易分解成二氧化碳挥发;薏米酸奶持水率在36.76%~44.80%,TB 的持水率为44.80%,显著高于RTB、RT 和RB(p<0.05);RTB 中活菌数达到9.99 log cfu/mL,显著高于2 株菌发酵的酸奶,这与前期实验结果一致,薏米促进Lactobacillus reuteri 的生长(p<0.05);薏米酸奶的蛋白质含量无显著差异(p<0.05)。

2.2 TPA

酸奶的硬度、弹性和内聚性是评价其质构特性的重要指标[26]。酸奶的凝乳结构主要是由酪蛋白、脂肪和乳清三部分形成的三维网状凝胶结构[22]。由表3 可知,RTB 酸奶咀嚼性(0.45 mj)、内聚性(0.77 Ratio)、胶黏性(0.05 N)均显著高于其他三个组,而硬度(0.69 N)、弹性(8.99 mj)显著高于RT 和RB,略低于TB(p<0.05),说明3 株菌发酵赋予薏米酸奶柔和的口感,表明3 株菌发酵薏米酸奶的整体凝固性较好,较黏稠,符合凝固型酸奶质构特性。

2.3 有机酸成分分析

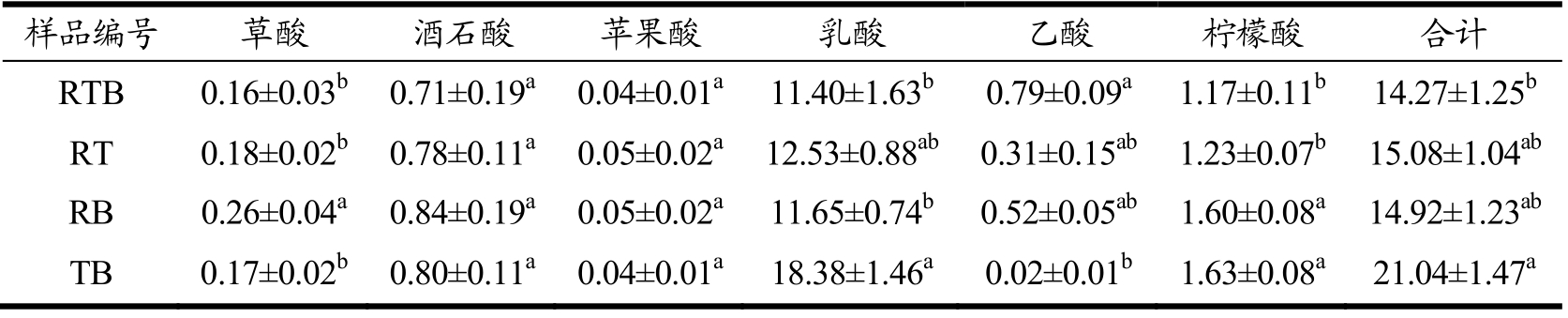

有机酸与发酵乳品质紧密相关[27]。由表4 可知,RTB、RT、RB和TB中有机酸含量分别是14.27、15.08、14.92、21.04 mg/mL。TB 中乳酸、柠檬酸含量最高,RTB 中乙酸(0.79 mg/mL)含量显著高于其它两菌发酵的酸奶(p<0.05),RB 中草酸(0.26 mg/mL)和酒石酸(0.84 mg/mL)含量最高。这与陈永福[28]研究结论一致,乳酸和柠檬酸是酸奶中的主要有机酸,酸奶的乳酸和柠檬酸与滴定酸度呈正相关,乙酸与滴定酸度呈负相关,这解释了RTB 中滴定酸度低和pH 高的结果。

表4 薏米酸奶中有机酸分析(mg/mL)

Table 4 Analysis of organic acids in semen coicis yogurt

样品编号 草酸 酒石酸 苹果酸 乳酸 乙酸 柠檬酸 合计RTB 0.16±0.03b 0.71±0.19a 0.04±0.01a 11.40±1.63b 0.79±0.09a 1.17±0.11b 14.27±1.25b RT 0.18±0.02b 0.78±0.11a 0.05±0.02a 12.53±0.88ab 0.31±0.15ab 1.23±0.07b 15.08±1.04ab RB 0.26±0.04a 0.84±0.19a 0.05±0.02a 11.65±0.74b 0.52±0.05ab 1.60±0.08a 14.92±1.23ab TB 0.17±0.02b 0.80±0.11a 0.04±0.01a 18.38±1.46a 0.02±0.01b 1.63±0.08a 21.04±1.47a

2.4 电子舌

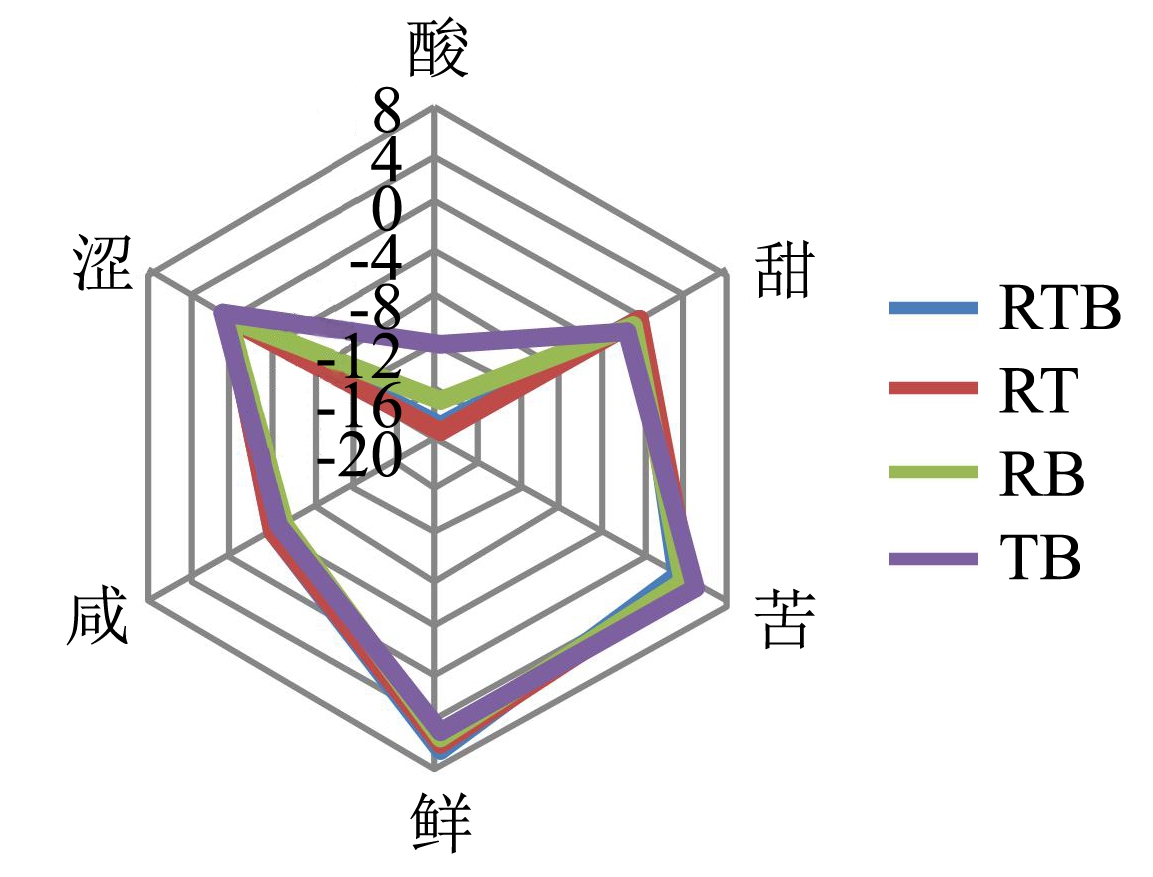

滋味是由酸、咸、鲜、甜、苦味组合而成,在酸奶中,这些人体能够鉴别的基本味觉主要由酸奶中非挥发性物质的组成及含量有关[29]。由图1 可知,四个样酸、甜、苦、鲜和咸味觉响应值均存在差异,酸味差异性最大,其次是鲜、咸、苦、甜涩(p<0.05),RTB甜味和鲜味最强,苦味、涩味和酸味最弱。

图1 酸奶味感雷达图

Fig.1 Yogurt taste radar map

2.5 挥发性风味物质分析

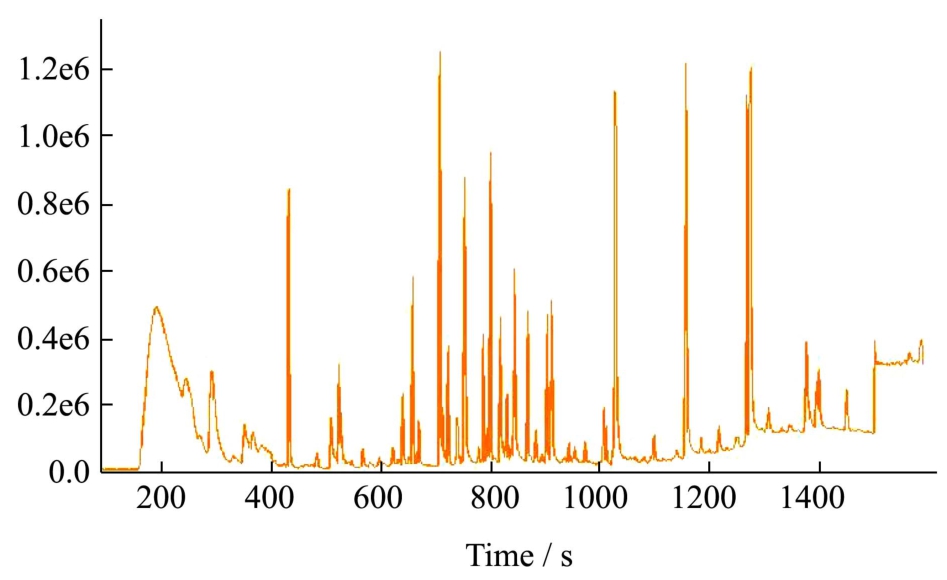

图2 薏米酸奶香气成分GC-MS 分析总离子流色谱图

Fig.2 Chromatogram of total ion flow of semen coicis yogurt aroma components analyzed by gc-ms

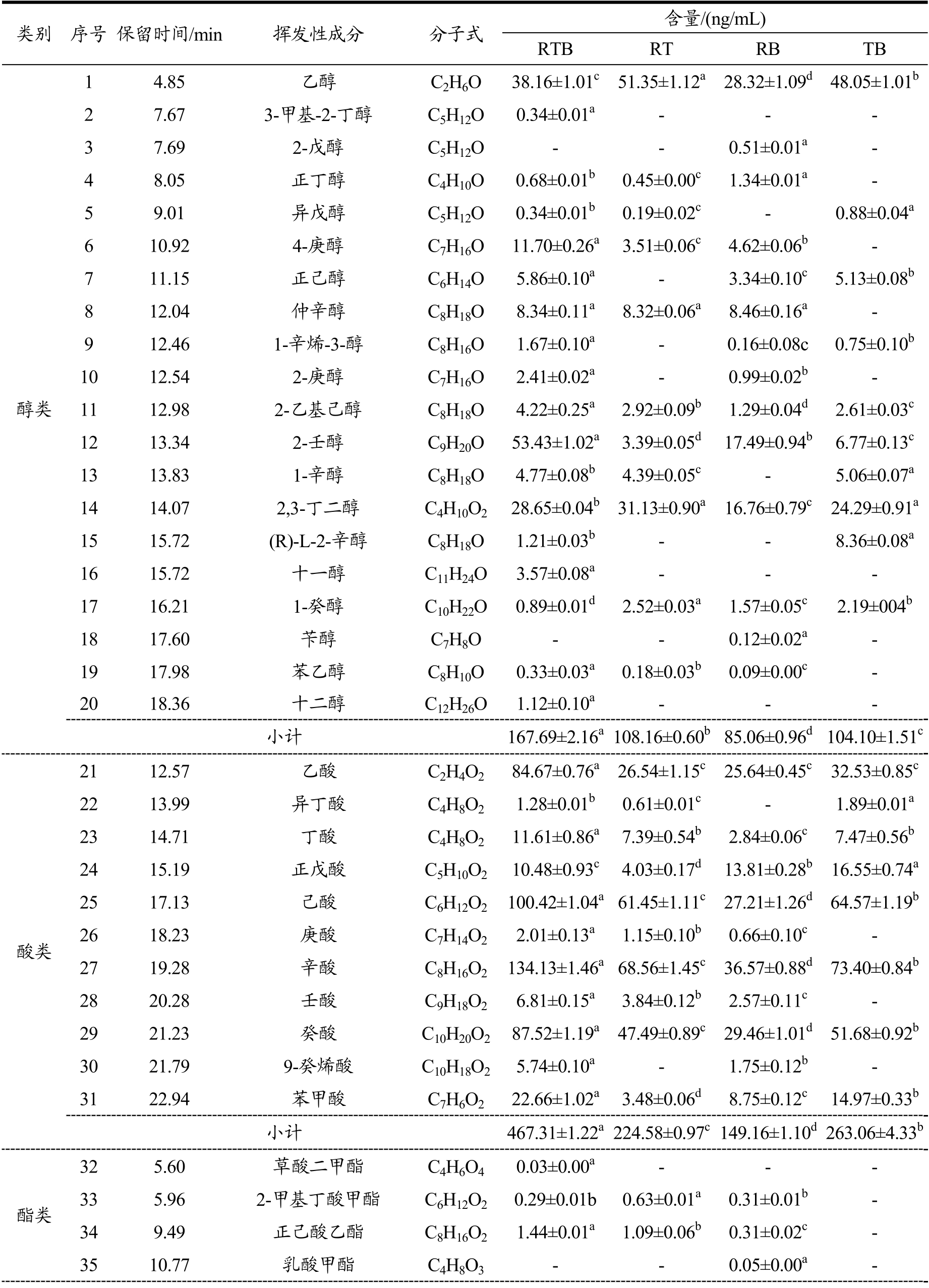

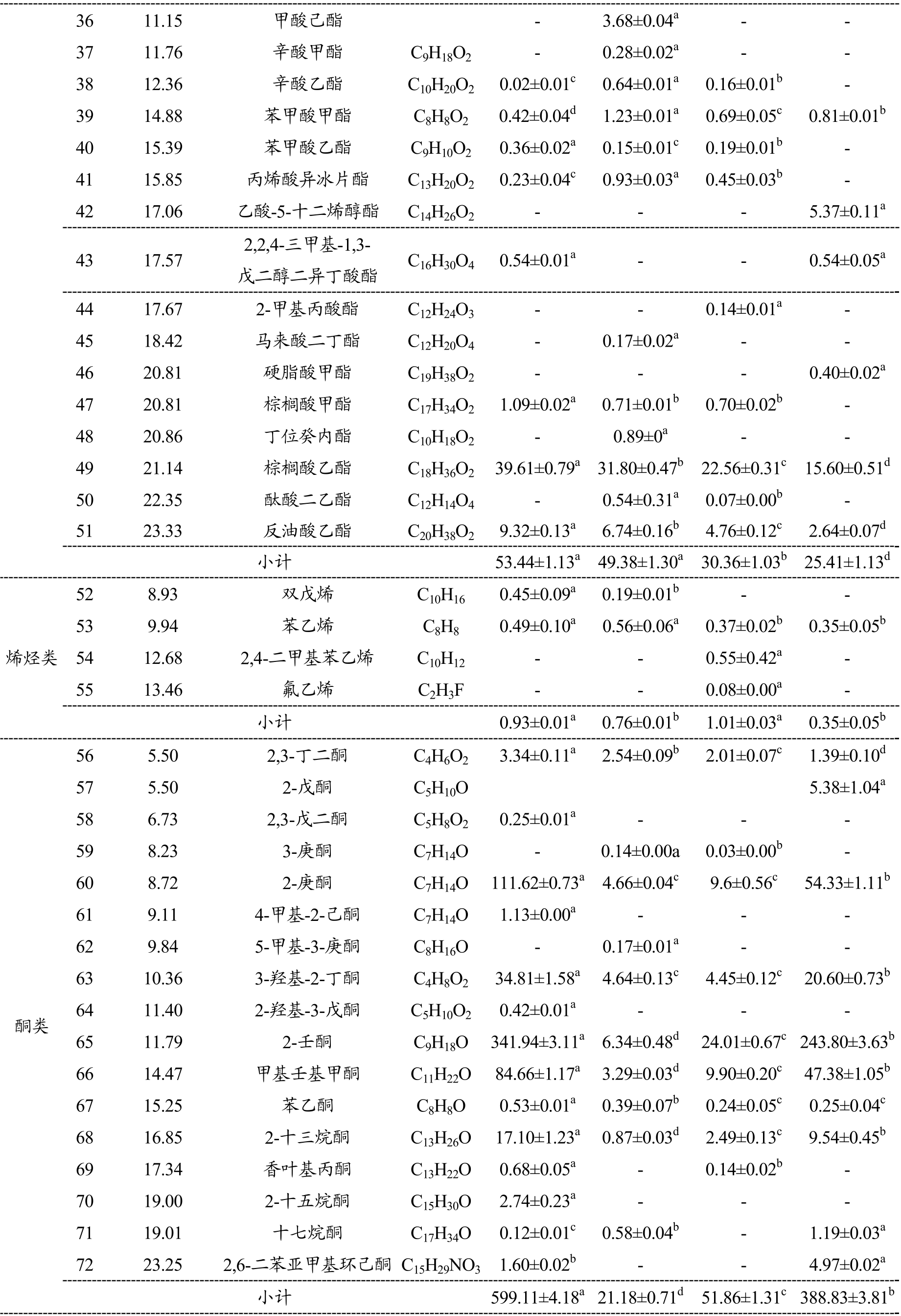

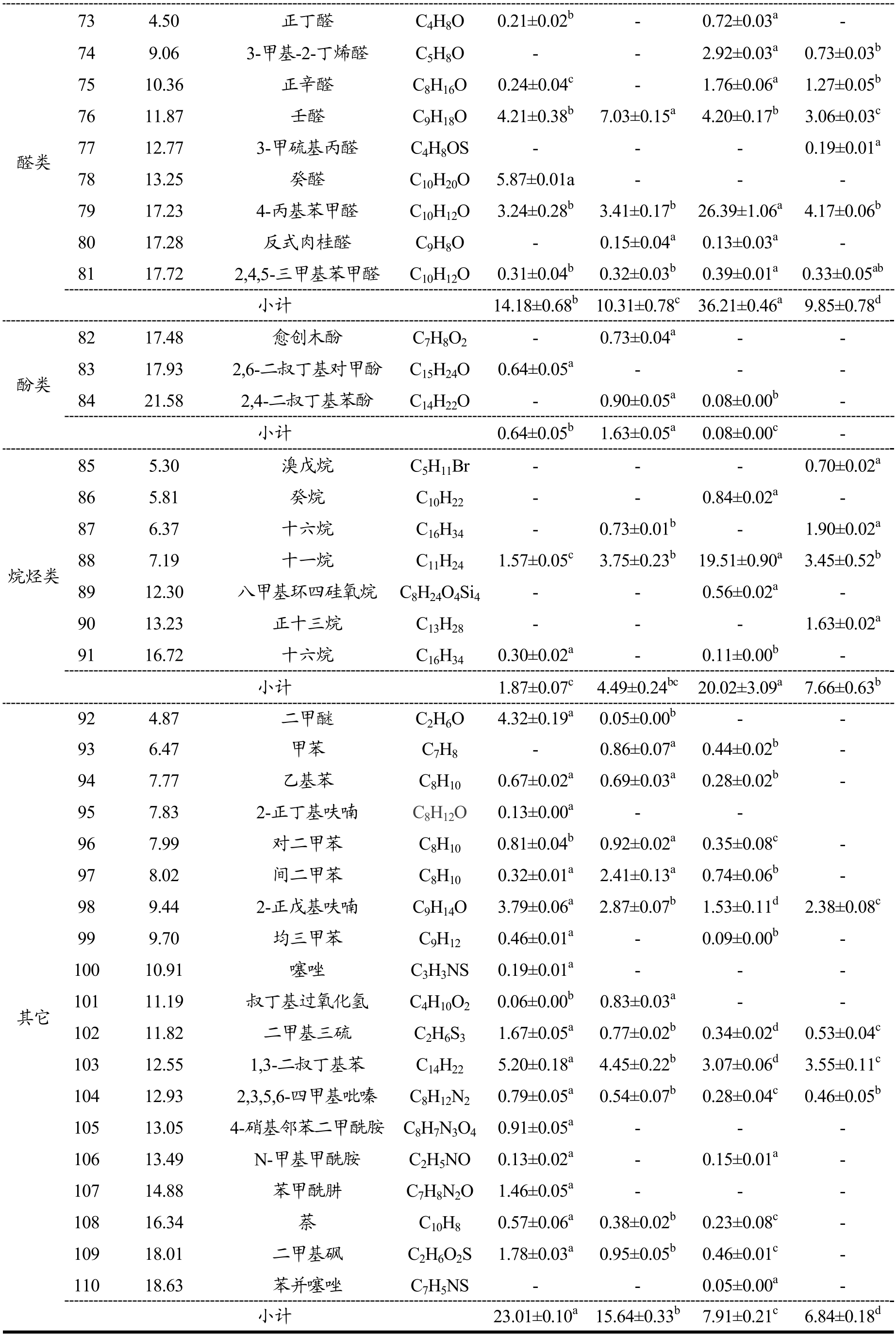

醇、醛、酮、酸、脂等共同决定了酸奶的风味[30],风味是决定酸奶的可接受性和选择性的重要因素[31]。由表5 可知,RTB、RT、RB 和TB 检测出总的风味物质依次为81 种(1331.74 ng/mL)、68 种(448.88 ng/mL)、73 种(388.74 ng/mL)和50 种(808.31 ng/mL),加入Lactobacillus reuteri 提高了薏米酸奶的风味物质种类和含量。

酸类物质是酸奶重要的风味物质,主要表现在酸奶的滋味上,RTB、RT、RB 和TB 检测出的酸分别为11 种(467.31 ng/mL)、10 种(224.58 ng/mL)、10 种(149.16 ng/mL)和8 种(263.06 ng/mL),酸奶样品中检测到含量较高的四种酸分别是辛酸、己酸、葵酸(87.52 和乙酸,且RTB 中辛酸(134.13 ng/mL)、己酸(100.42 ng/mL)、葵酸(87.52 ng/mL)和乙酸(84.67 ng/mL)显著高于其它2 株菌发酵的酸奶(p<0.05),RTB 中乙酸含量较高这与Vénica C I 研究一致,益生菌通过异发酵途径生产乙酸有关[32]。癸酸能增加酸奶奶香味,己酸具有的椰果香味,戊酸表现出奶油香味,丁酸、庚酸具有奶酪香[33]。这些特殊的酸赋予了薏米酸奶独特的味道。

醇类物质的阈值较高,对酸奶风味物质的影响很小,但是醇可转化为酸,也是必不可少的一类物质。RTB、RT、RB 和TB 检测出的醇依次为18 种(167.75 ng/mL)、11 种(108.16 ng/mL)、14 种(85.11 ng/mL)、10 种(104.09 ng/mL)。四个样中含量较高的四种醇分别是乙醇(38.16 ng/mL)、2-壬醇(53.43 ng/mL)、2,3 丁二醇(28.65 ng/mL)和4-庚醇(11.70 ng/mL),2-壬醇和4-庚醇在RTB 中最高,乙醇和2,3 丁二醇在RT 中最高。

酮类物质由多不饱和脂肪酸的氧化、热降解,氨基酸降解或微生物代谢产生[34]。RTB、RT、RB 和TB检测出的酮依次为14 种(599.11 ng/mL)、10 种(21.18 ng/mL)、9 种(51.86 ng/mL)、10 种(388.83 ng/mL);酸奶在发酵过程中经过复杂的生物化学反应,使酸奶具有特有的风味,在所有风味物质中2-壬酮含量最高,为341.94 ng/mL,它能够给酸奶提供独有的清香味,RTB 中2-壬酮含量显著高于其它两菌发酵酸奶。3-羟基-2-丁酮具有浓郁的奶香味,在RTB 中含量最高,达到34.81 ng/mL;丁二酮具有浓郁的奶油味,在RTB中含量最高,达到3.34 ng/mL;2-庚酮有类似梨的水果香味,在RTB 中含量为111.62 ng/mL 显著高于其它两菌发酵酸奶。2,3-戊二酮具有奶油、焦糖香气,并带有坚果香,只在RTB 中检测到。

表5 薏米酸奶主要风味物质种类与含量分析

Table 5 Main flavor substances and content analysis of semen coicis yogurt

类别 序号 保留时间/min 挥发性成分 分子式 含量/(ng/mL)RTB RT RB TB 1 4.85 乙醇 C2H6O 38.16±1.01c 51.35±1.12a 28.32±1.09d 48.05±1.01b醇类酸类酯类2 7.67 3-甲基-2-丁醇 C5H12O 0.34±0.01a - - -3 7.69 2-戊醇 C5H12O - - 0.51±0.01a -4 8.05 正丁醇 C4H10O 0.68±0.01b 0.45±0.00c 1.34±0.01a -5 9.01 异戊醇 C5H12O 0.34±0.01b 0.19±0.02c - 0.88±0.04a 6 10.92 4-庚醇 C7H16O 11.70±0.26a 3.51±0.06c 4.62±0.06b -7 11.15 正己醇 C6H14O 5.86±0.10a - 3.34±0.10c 5.13±0.08b 8 12.04 仲辛醇 C8H18O 8.34±0.11a 8.32±0.06a 8.46±0.16a -9 12.46 1-辛烯-3-醇 C8H16O 1.67±0.10a - 0.16±0.08c 0.75±0.10b 10 12.54 2-庚醇 C7H16O 2.41±0.02a - 0.99±0.02b -11 12.98 2-乙基己醇 C8H18O 4.22±0.25a 2.92±0.09b 1.29±0.04d 2.61±0.03c 12 13.34 2-壬醇 C9H20O 53.43±1.02a 3.39±0.05d 17.49±0.94b 6.77±0.13c 13 13.83 1-辛醇 C8H18O 4.77±0.08b 4.39±0.05c - 5.06±0.07a 14 14.07 2,3-丁二醇 C4H10O2 28.65±0.04b 31.13±0.90a 16.76±0.79c 24.29±0.91a 15 15.72 (R)-L-2-辛醇 C8H18O 1.21±0.03b - - 8.36±0.08a 16 15.72 十一醇 C11H24O 3.57±0.08a - - -17 16.21 1-癸醇 C10H22O 0.89±0.01d 2.52±0.03a 1.57±0.05c 2.19±004b 18 17.60 苄醇 C7H8O - - 0.12±0.02a -19 17.98 苯乙醇 C8H10O 0.33±0.03a 0.18±0.03b 0.09±0.00c -20 18.36 十二醇 C12H26O 1.12±0.10a - - -小计 167.69±2.16a 108.16±0.60b 85.06±0.96d 104.10±1.51c 21 12.57 乙酸 C2H4O2 84.67±0.76a 26.54±1.15c 25.64±0.45c 32.53±0.85c 22 13.99 异丁酸 C4H8O2 1.28±0.01b 0.61±0.01c - 1.89±0.01a 23 14.71 丁酸 C4H8O2 11.61±0.86a 7.39±0.54b 2.84±0.06c 7.47±0.56b 24 15.19 正戊酸 C5H10O2 10.48±0.93c 4.03±0.17d 13.81±0.28b 16.55±0.74a 25 17.13 己酸 C6H12O2 100.42±1.04a 61.45±1.11c 27.21±1.26d 64.57±1.19b 26 18.23 庚酸 C7H14O2 2.01±0.13a 1.15±0.10b 0.66±0.10c -27 19.28 辛酸 C8H16O2 134.13±1.46a 68.56±1.45c 36.57±0.88d 73.40±0.84b 28 20.28 壬酸 C9H18O2 6.81±0.15a 3.84±0.12b 2.57±0.11c -29 21.23 癸酸 C10H20O2 87.52±1.19a 47.49±0.89c 29.46±1.01d 51.68±0.92b 30 21.79 9-癸烯酸 C10H18O2 5.74±0.10a - 1.75±0.12b -31 22.94 苯甲酸 C7H6O2 22.66±1.02a 3.48±0.06d 8.75±0.12c 14.97±0.33b小计 467.31±1.22a 224.58±0.97c 149.16±1.10d 263.06±4.33b 32 5.60 草酸二甲酯 C4H6O4 0.03±0.00a - - -33 5.96 2-甲基丁酸甲酯 C6H12O2 0.29±0.01b 0.63±0.01a 0.31±0.01b -34 9.49 正己酸乙酯 C8H16O2 1.44±0.01a 1.09±0.06b 0.31±0.02c -35 10.77 乳酸甲酯 C4H8O3 - - 0.05±0.00a -

烯烃类酮类36 11.15 甲酸己酯 - 3.68±0.04a - -37 11.76 辛酸甲酯 C9H18O2 - 0.28±0.02a - -38 12.36 辛酸乙酯 C10H20O2 0.02±0.01c 0.64±0.01a 0.16±0.01b -39 14.88 苯甲酸甲酯 C8H8O2 0.42±0.04d 1.23±0.01a 0.69±0.05c 0.81±0.01b 40 15.39 苯甲酸乙酯 C9H10O2 0.36±0.02a 0.15±0.01c 0.19±0.01b -41 15.85 丙烯酸异冰片酯 C13H20O2 0.23±0.04c 0.93±0.03a 0.45±0.03b -42 17.06 乙酸-5-十二烯醇酯 C14H26O2 - - - 5.37±0.11a 43 17.57 2,2,4-三甲基-1,3-戊二醇二异丁酸酯 C16H30O4 0.54±0.01a - - 0.54±0.05a 44 17.67 2-甲基丙酸酯 C12H24O3 - - 0.14±0.01a -45 18.42 马来酸二丁酯 C12H20O4 - 0.17±0.02a - -46 20.81 硬脂酸甲酯 C19H38O2 - - - 0.40±0.02a 47 20.81 棕榈酸甲酯 C17H34O2 1.09±0.02a 0.71±0.01b 0.70±0.02b -48 20.86 丁位癸内酯 C10H18O2 - 0.89±0a - -49 21.14 棕榈酸乙酯 C18H36O2 39.61±0.79a 31.80±0.47b 22.56±0.31c 15.60±0.51d 50 22.35 酞酸二乙酯 C12H14O4 - 0.54±0.31a 0.07±0.00b -51 23.33 反油酸乙酯 C20H38O2 9.32±0.13a 6.74±0.16b 4.76±0.12c 2.64±0.07d小计 53.44±1.13a 49.38±1.30a 30.36±1.03b 25.41±1.13d 52 8.93 双戊烯 C10H16 0.45±0.09a 0.19±0.01b - -53 9.94 苯乙烯 C8H8 0.49±0.10a 0.56±0.06a 0.37±0.02b 0.35±0.05b 54 12.68 2,4-二甲基苯乙烯 C10H12 - - 0.55±0.42a -55 13.46 氟乙烯 C2H3F - - 0.08±0.00a -小计 0.93±0.01a 0.76±0.01b 1.01±0.03a 0.35±0.05b 56 5.50 2,3-丁二酮 C4H6O2 3.34±0.11a 2.54±0.09b 2.01±0.07c 1.39±0.10d 57 5.50 2-戊酮 C5H10O 5.38±1.04a 58 6.73 2,3-戊二酮 C5H8O2 0.25±0.01a - - -59 8.23 3-庚酮 C7H14O - 0.14±0.00a 0.03±0.00b -60 8.72 2-庚酮 C7H14O 111.62±0.73a 4.66±0.04c 9.6±0.56c 54.33±1.11b 61 9.11 4-甲基-2-己酮 C7H14O 1.13±0.00a - - -62 9.84 5-甲基-3-庚酮 C8H16O - 0.17±0.01a - -63 10.36 3-羟基-2-丁酮 C4H8O2 34.81±1.58a 4.64±0.13c 4.45±0.12c 20.60±0.73b 64 11.40 2-羟基-3-戊酮 C5H10O2 0.42±0.01a - - -65 11.79 2-壬酮 C9H18O 341.94±3.11a 6.34±0.48d 24.01±0.67c 243.80±3.63b 66 14.47 甲基壬基甲酮 C11H22O 84.66±1.17a 3.29±0.03d 9.90±0.20c 47.38±1.05b 67 15.25 苯乙酮 C8H8O 0.53±0.01a 0.39±0.07b 0.24±0.05c 0.25±0.04c 68 16.85 2-十三烷酮 C13H26O 17.10±1.23a 0.87±0.03d 2.49±0.13c 9.54±0.45b 69 17.34 香叶基丙酮 C13H22O 0.68±0.05a - 0.14±0.02b -70 19.00 2-十五烷酮 C15H30O 2.74±0.23a - - -71 19.01 十七烷酮 C17H34O 0.12±0.01c 0.58±0.04b - 1.19±0.03a 72 23.25 2,6-二苯亚甲基环己酮C15H29NO3 1.60±0.02b - - 4.97±0.02a小计 599.11±4.18a 21.18±0.71d 51.86±1.31c 388.83±3.81b

注:“-”表示未检出。

醛类酚类烷烃类其它73 4.50 正丁醛 C4H8O 0.21±0.02b - 0.72±0.03a -74 9.06 3-甲基-2-丁烯醛 C5H8O - - 2.92±0.03a 0.73±0.03b 75 10.36 正辛醛 C8H16O 0.24±0.04c - 1.76±0.06a 1.27±0.05b 76 11.87 壬醛 C9H18O 4.21±0.38b 7.03±0.15a 4.20±0.17b 3.06±0.03c 77 12.77 3-甲硫基丙醛 C4H8OS - - - 0.19±0.01a 78 13.25 癸醛 C10H20O 5.87±0.01a - - -79 17.23 4-丙基苯甲醛 C10H12O 3.24±0.28b 3.41±0.17b 26.39±1.06a 4.17±0.06b 80 17.28 反式肉桂醛 C9H8O - 0.15±0.04a 0.13±0.03a -81 17.72 2,4,5-三甲基苯甲醛 C10H12O 0.31±0.04b 0.32±0.03b 0.39±0.01a 0.33±0.05ab小计 14.18±0.68b 10.31±0.78c 36.21±0.46a 9.85±0.78d 82 17.48 愈创木酚 C7H8O2 - 0.73±0.04a - -83 17.93 2,6-二叔丁基对甲酚 C15H24O 0.64±0.05a - - -84 21.58 2,4-二叔丁基苯酚 C14H22O - 0.90±0.05a 0.08±0.00b -小计 0.64±0.05b 1.63±0.05a 0.08±0.00c -85 5.30 溴戊烷 C5H11Br - - - 0.70±0.02a 86 5.81 癸烷 C10H22 - - 0.84±0.02a -87 6.37 十六烷 C16H34 - 0.73±0.01b - 1.90±0.02a 88 7.19 十一烷 C11H24 1.57±0.05c 3.75±0.23b 19.51±0.90a 3.45±0.52b 89 12.30 八甲基环四硅氧烷 C8H24O4Si4 - - 0.56±0.02a -90 13.23 正十三烷 C13H28 - - - 1.63±0.02a 91 16.72 十六烷 C16H34 0.30±0.02a - 0.11±0.00b -小计 1.87±0.07c 4.49±0.24bc 20.02±3.09a 7.66±0.63b 92 4.87 二甲醚 C2H6O 4.32±0.19a 0.05±0.00b - -93 6.47 甲苯 C7H8 - 0.86±0.07a 0.44±0.02b -94 7.77 乙基苯 C8H10 0.67±0.02a 0.69±0.03a 0.28±0.02b -95 7.83 2-正丁基呋喃 C8H12O 0.13±0.00a - -96 7.99 对二甲苯 C8H10 0.81±0.04b 0.92±0.02a 0.35±0.08c -97 8.02 间二甲苯 C8H10 0.32±0.01a 2.41±0.13a 0.74±0.06b -98 9.44 2-正戊基呋喃 C9H14O 3.79±0.06a 2.87±0.07b 1.53±0.11d 2.38±0.08c 99 9.70 均三甲苯 C9H12 0.46±0.01a - 0.09±0.00b -100 10.91 噻唑 C3H3NS 0.19±0.01a - - -101 11.19 叔丁基过氧化氢 C4H10O2 0.06±0.00b 0.83±0.03a - -102 11.82 二甲基三硫 C2H6S3 1.67±0.05a 0.77±0.02b 0.34±0.02d 0.53±0.04c 103 12.55 1,3-二叔丁基苯 C14H22 5.20±0.18a 4.45±0.22b 3.07±0.06d 3.55±0.11c 104 12.93 2,3,5,6-四甲基吡嗪 C8H12N2 0.79±0.05a 0.54±0.07b 0.28±0.04c 0.46±0.05b 105 13.05 4-硝基邻苯二甲酰胺 C8H7N3O4 0.91±0.05a - - -106 13.49 N-甲基甲酰胺 C2H5NO 0.13±0.02a - 0.15±0.01a -107 14.88 苯甲酰肼 C7H8N2O 1.46±0.05a - - -108 16.34 萘 C10H8 0.57±0.06a 0.38±0.02b 0.23±0.08c -109 18.01 二甲基砜 C2H6O2S 1.78±0.03a 0.95±0.05b 0.46±0.01c -110 18.63 苯并噻唑 C7H5NS - - 0.05±0.00a -小计 23.01±0.10a 15.64±0.33b 7.91±0.21c 6.84±0.18d

酯类物质是酸奶的重要风味物质。酸奶酯类物质主要通过脂肪酸水解以及微生物的代谢生成,特别是原料乳中的短链脂肪酸水解会产生甲基酮和内酯,能够直接影响酸奶的整体风味。RTB、RT、RB 和TB中检测出的脂为11 种(53.44 ng/mL)、14 种(49.38 ng/mL)、12 种(30.36 ng/mL)、6 种(25.41 ng/mL)。乙酯类化合物具有水果花香味,可减少酸奶的苦味和酸味[35],在RTB 中含量最高,为50.73 ng/mL,这与前文RTB 中滴定酸度最低、有机酸含量最低和质构中苦味最弱结果一致。

醛类物质是酸奶中重要的风味物质。RTB、RT、RB 和TB 中出的醛为6 种(14.18 ng/mL)、4 种(10.31 ng/mL)、7 种(36.21 ng/mL)、6 种(9.85 ng/mL)。壬醛会产生蜡香、蜂蜜香等,在RT 中含量最高,为4.21 ng/mL;癸醛微甜,有类似于甜橙油和玫瑰油的味道,散发出新鲜的柑橘皮的清香味,只在RTB 中检测出。

综上,3 株菌发酵酸奶的醇、酸、脂、酮都显著高于其他2 株菌发酵的样品,对3 株菌发酵酸奶贡献性较大的是酮类、酸类,含量最大的四种物质是2-壬酮(341.94 ng/mL)、2-庚酮(111.62 ng/mL)、辛酸(134.13 ng/mL)、己酸(100.42 ng/mL)。3 株菌发酵中的醇、酸、脂、酮等含量分布较为分散、合理,3株菌发酵提高了酸奶风味物质种类和含量,3 株菌发酵的酸奶风味更均衡。

3 结论

3 株菌协同发酵显著提高酸奶的活菌数(9.99 log cfu/mL)、咀嚼性(0.45 mj)、内聚性(0.73 Ratio)、胶黏性(0.05 N)、乙酸含量(0.79 mg/mL)、甜味和鲜味味觉响应值,显著减弱酸奶的苦味、涩味、酸味味觉响应值(p<0.05);3 株菌发酵酸奶的风味物质为81 种(1331.74 ng/mL),种类、含量显著高于2 株菌发酵的酸奶,且其中的醇、酸、酸、酮含量都显著高于两菌发酵的样品(p<0.05)。3 株菌协同发酵薏米酸奶的整体凝固性较好、质构特性较好、滋味适中、风味物质种类较多和含量较高,并且酸奶具有薏米独特的谷物香味,为Lactobacillus reuteri 在乳制品中的应用及薏米产品的深入研发提供理论依据。

[1] Lim S-M, Lee N-K, Kim K-T, et al. Probiotic Lactobacillus fermentum KU200060 isolated from watery kimchi and its application in probiotic yogurt for oral health [J]. Microbial Pathogenesis, 2020, 147: 104430

[2] E G S, L S M. Deconjugation of bile acids by intestinal lactobacilli [J]. Applied and Environmental Microbiology,1977, 33(1): 15-18

[3] Kullisaar T, Songisepp E, Mikelsaar M, et al. Antioxidative probiotic fermented goats" milk decreases oxidative stress-mediated atherogenicity in human subjects [J]. British Journal of Nutrition, 2003, 90(2): 449-456

[4] Eda E M, Sibel K. Influence of the addition of chia seeds and germinated seeds and sprouts on the nutritional and beneficial properties of yogurt [J]. International Journal of Gastronomy and Food Science, 2020, 22: 100276

[5] Carr F J, Chill D, Maida N. The lactic acid bacteria: a literature survey [J]. Critical Reviews in Microbiology, 2002,28(4): 281-370

[6] 王霄鹏.益生菌的降脂作用及其功能性乳的研究[D].西安:陕西科技大学,2016

WANG Xiao-peng. Study on lipid lowering effect and functional milk of probiotics [D]. Xi`an: Shaanxi University of Science and Technology, 2016

[7] 童秦怡.霍山石斛汁功能性酸奶的研究[D].芜湖:安徽工程大学,2019

TONG Qin-yi. Study on functional yoghurt from Dendrobium Huoshan [D]. Wuhu: Anhui University of Engineering, 2019

[8] 何云侠.干酪乳杆菌微胶囊的制备及应用[D].西安:陕西科技大学,2019

HE Yun-xia. Preparation and application of Lactobacillus casei microcapsules [D]. Xi`an: Shaanxi University of Science and Technology, 2019

[9] Cui L, Chang S K C, Nannapaneni R. Comparative studies on the effect of probiotic additions on the physicochemical and microbiological properties of yoghurt made from soymilk and cow"s milk during refrigeration storage (R2) [J].Food Control, 2021, 119: 107474

[10] Miao L, Zhao S, Zhang B, et al. Understanding the supramolecular structures and pasting features of adlay seed starches [J]. Food Hydrocolloids, 2018, 83: 411-418

[11] Yu F, Zhang J, Li Y-Z, et al. Research and application of adlay in medicinal field [J]. Chinese Herbal Medicines, 2017,9(2): 126-133

[12] 金锋.薏米酸奶加工工艺研究[J].农业科技与装备,2012,3:58-60,4

JIN Feng. Research on processing technology of semen coicis yogurt [J]. Agricultural Science and Technology &Equipment, 2012, 3: 58-60, 4

[13] 李正华.罗伊氏乳杆菌生物学特性及功能性发酵乳的研究[D].无锡:江南大学,2008

LI Zheng-hua. Study on biological characteristics and functional fermented milk of Lactobacillus reuteri [D]. Wuxi:Jiangnan University, 2008

[14] Ortiz-rivera Y, Sánchez-vega R, Gutiérrez-méndez N, et al.Production of reuterin in a fermented milk product by Lactobacillus reuteri: inhibition of pathogens, spoilage microorganisms, and lactic acid bacteria [J]. Journal of Dairy Science, 2017, 100(6): 4258-4268

[15] 庞洁,周娜,刘鹏,等.罗伊氏乳杆菌的益生功能[J].中国生物工程杂志,2011,31(5):131-137

PANG Jie, ZHOU Na, LIU Peng, et al. Probiotics of Lactobacillus reuteri [J]. Chinese Journal of Bioengineering,2011, 31(5): 131-137

[16] Coccorullo P, Strisciuglio C, Martinelli M, et al.Lactobacillus reuteri (DSM 17938) in infants with functional chronic constipation: a double-blind, randomized,placebo-controlled study [J]. The Journal of Pediatrics, 2010,157(4): 598-602

[17] Su C, Lin C, Lie C, et al. Potential probiotic characterization of Lactobacillus reuteri from traditional Chinese highland barley wine and application for room-temperature-storage drinkable yogurt [J]. Journal of Dairy Science, 2018,101(7):5780-5788

[18] Li M, Jin Y, Wang Y, et al. Preparation of Bifidobacterium breve encapsulated in low methoxyl pectin beads and its effects on yogurt quality [J]. Journal of Dairy Science, 2019,102(6):4832-4843

[19] Feng C, Wang B, Zhao A, et al. Quality characteristics and antioxidant activities of goat milk yogurt with added jujube pulp [J]. Food Chemistry, 2019, 277(30): 238-245

[20] Fang T, Shen X, Hou J, et al. Effects of polymerized whey protein prepared directly from cheese whey as fat replacer on physiochemical, texture, microstructure and sensory properties of low-fat set yogurt [J]. LWT, 2019, 115: 108268

[21] 王雪艳.西藏高海拔地区酸奶中乳酸菌分离鉴定及其产酸能力评价[D].拉萨:西藏大学,2016

WANG Xue-yan. Isolation and identification of lactic acid bacteria from yogurt in high altitude area of Xizang province and evaluation of its acid production capacity [D]. Lasa:Xizang University, 2016

[22] 王一然.发酵条件对酸奶营养品质及代谢产物的影响[D].沈阳:沈阳农业大学,2019

WANG Yi-ran. Effects of fermentation conditions on nutritional quality and metabolites of yogurt [D]. Shenyang:Shenyang Agricultural University, 2019

[23] Moineau-jean A, Raymond Y, Sabik H, et al. Effect of manufacturing processes and storage on aroma compounds and sensory properties of yoghurt [J]. International Dairy Journal, 2020, 105: 104662

[24] 王然,项铁男,刘颖,等.添加茶油胶对植物油基酸奶品质特性的影响[J].中国酿造,2020,39(9):195-199

WANG Ran, XIANG Tie-nan, LIU Ying, et al. Effect of camellia oil glue on the quality and characteristics of vegetable oil-based yogurt [J]. China Brewing, 2020, 39(9):195-199

[25] 温夏萍,王呈,弓耀忠.罗伊氏乳杆菌发酵对酸乳营养价值的影响[J].中国奶牛,2019,5:41-44

WEN Xia-ping, WANG Cheng, GONG Yao-zhong. Effects of Lactobacillus reuteri fermentation on the nutritional value of yoghurt [J]. Chinese Dairy Cows, 2019, 5: 41-44

[26] 王清爽,高珊,朱灵灵,等.干酪乳杆菌发酵对发芽薏米营养组成和生物活性的影响[J].中国粮油学报,2020,35(4):12-18

WANG Qing-shuang, GAO Shan, ZHU Ling-ling, et al.Effects of Lactobacillus casei fermentation on the nutritional composition and biological activity of semen coicis germination [J]. Chinese Journal of Cereals and Oils, 2020,35(4): 12-18

[27] Buffa M N, Guamis B, Saldo J, et al. Changes in organic acids during ripening of cheeses made from raw, pasteurized or high-pressure-treated goats’ milk [J]. LWT - Food Science and Technology, 2004, 37(2): 247-253

[28] 陈永福,王记成,云振宇,等.高效液相色谱法测定传统发酵乳中的有机酸组成[J].中国乳品工业,2007,1:54-58

CHEN Yong-fu, WANG Ji-cheng, YUN Zhen-yu, et al.Determination of organic acid composition in traditional fermented milk by high performance liquid chromatography[J]. Chinese Dairy Industry, 2007, 1: 54-58

[29] 耿明雪,刘小鸣,赵建新,等.基于组学及感官评价的酸奶风味研究[J].食品与发酵工业,2018,44(7):250-257

GENG Ming-xue, LIU Xiao-ming, ZHAO Jian-xin, et al.Study on yogurt flavor based on omics and sensory evaluation [J]. Food and Fermentation Industry, 2018, 44(7):250-257

[30] 王静波.苦荞复配酸奶的研制及其品质分析[D].成都:西华大学,2013

WANG Jing-bo. Preparation and quality analysis of Tartary buckwheat mixed with yoghurt [D]. Chengdu: Xihua University, 2013

[31] Zhao L, Feng R, Ren F, et al. Addition of buttermilk improves the flavor and volatile compound profiles of low-fat yogurt [J]. LWT, 2018, 98: 9-17

[32] Vénica C I, Bergamini C V, Rebechi S R, et al.Galacto-oligosaccharides formation during manufacture of different varieties of yogurt. Stability through storage [J].LWT - Food Science and Technology, 2015, 63(1): 198-205

[33] 刘梅森,何唯平,赖敬财,等.奶粉脂肪酸与乳制品风味关系研究[J].中国乳品工业,2008,2:13-15

LIU Mei-sen, HE Wei-ping, LAI Jing-cai, et al. Relationship between fatty acids in milk powder and flavor of dairy products [J]. Chinese Dairy Industry, 2008, 2: 13-15

[34] 李广富,陈伟,范路平,等.灵芝功能成分酸奶营养品质与风味物质分析[J].食品科学,2015,36(10):168-173

LI Guang-fu, CHEN Wei, FAN Lu-ping, et al. Analysis of nutritional quality and flavor of functional components of Ganoderma lucidum yogurt [J]. Food Science, 2015, 36(10):168-173

[35] 王富云,王成财,王哲铭,等.虾青素微球对酸奶品质与风味的影响 [J].食品科学 ,2020-7-22,https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&d bname=CAPJLAST&filename=SPKX2020072001M&v=17 WwU59A5kC8jB7UYAWL3Kn1IHB3bUFqrAbdX6WX42 AOOcFcLwHTm4G0wey7SS16

WANG Fu-yun, WANG Cheng-cai, WANG Zhe-ming, et al.Effect of astaxanthin microspheres on quality and flavor of yogurt [J]. Food Science, 2020-7-22,https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&d bname=CAPJLAST&filename=SPKX2020072001M&v=17 WwU59A5kC8jB7UYAWL3Kn1IHB3bUFqrAbdX6WX42 AOOcFcLwHTm4G0wey7SS16